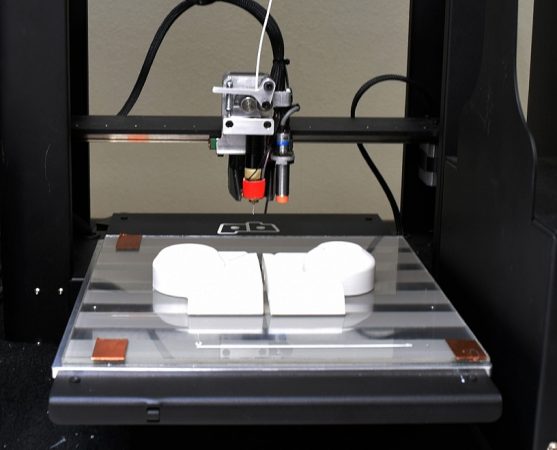

Ever wanted to 3D print on a glass bed? Here are 7 reasons why we think it's a good idea.

3D Printing on glass is an easy and relatively low-cost upgrade for your FDM style 3D printer. We have found a bare glass surface to be the sweet spot between too much and too little adhesion for PLA and PETG filaments. Too little adhesion leads to the part lifting and warping which can lead to failed prints and deformed parts. Too much adhesion makes it very difficult to remove the parts even after they cool. We have tested 0.125 inch standard soda-lime glass and borosilicate glass and have found borosilicate glass to withstand higher temperatures needed for certain filaments. For safety reasons alone, borosilicate is worth the higher costs.

In our experience, printing on bare glass requires a heated bed. Spending a bit of time to get the surface temperature dialed will give consistent prints without warping. From our testing, 60°C surface temperature of the glass is ideal for printing with PLA. 75°C is best for PETG. Because of the lower thermal conductivity of glass, the temperature will drop as the heat transfers through the glass. This usually requires setting your printer’s print temperature to a value 2-15°C above the suggested surface temperature number depending on your setup. I recommend using an infrared thermometer to dial in to the recommended temperature. You can purchase one here for under $15.

In our experience, ABS and nylon filament requires additional surface adhesion methods. If you are set on using either of these, then stick to commonly used methods such as hair spray, PVA-based glue stick, blue painter’s tape, kapton tape, or proprietary bed adhesion solutions.

Lastly, it is important to have an effective means to hold the glass in place. We suggest one of two methods. Use a non-adhesive thermal pad to hold the glass in place and to provide sufficient heat transfer from the aluminum surface underneath. You can purchase thermal pad here or here. The other option is to use clips to hold the glass directly to the aluminum. Make sure the clips are strong enough to hold the glass without allowing it to shift side to side. You can purchase them here or print them yourself!

- Long Term Cost

Due to the durability of glass, you pay only a one-time cost to upgrade your printer. All other methods require either replacement or reapplication at some point. In the long run, glass will save you money and hassle.

- One-Time Setup

Glass install on your 3D printer should be a one-time occurrence. Some other bed surfaces will require replacement over time and the bed leveling will have to be recalibrated. Other popular adhesion promoters such as hair spray, PVA-based glue stick, and other liquid bed adhesion solutions require clean-up and reapplication between every print.

- Surface Finish

Glass provides glossy, mirror-like surface to the face down portion of your parts. Unlike other print bed surfaces, glass does not develop imperfections that then transfer directly to your parts. You will marvel at the consistency of the mirror finish on your parts.

- Consistent Flatness

Since glass is manufactured to have a flat surface, it will help ensure the leveling of your bed stays consistent print after print. Having to constantly change the level adjustments or settings on your printer can be a pain. Since glass is thermally stable and has a high modulus of elasticity, it remains flat and in place during the print.

- Easy Removal

As the parts cool after the print, they will contract to a greater amount relative to the glass. This causes the part’s surface to pop off the glass for easy removal, with no force required. Other methods adhere the part so well that you have to hit them with a hammer or chisel to remove.

- Easy Clean-up

Glass beds are very easy to clean and easy to spot dirt, dust, grease, or plastic fragments on. We recommend occasionally wiping the bed with standard glass cleaner to remove grease and use a microfiber cloth to prevent streaking. Glass cleaner seems to be more effective and safer than Isopropyl Alcohol and Acetone.

- Durability

Many of the alternative adhesion methods such as blue painter’s tape, kapton tape, and plastic print surface sheets do not withstand repeated use. Depending on usage, these surfaces may only last a few prints before requiring replacement. However, glass never wears out or needs replacement and you can continue printing without worrying about replacement.

Links to Parts

- Borosilicate Glass Plate

- Glass Cleaner

- Microfiber Cloth

- Thermal Pad

- Option 1

- Option 2 - Clips

- Option 1

- Option 2 - Infrared Thermometer

This article was published by OhmniLabs, a member of the Kambria Manufacturing Alliance. Please follow their blog for more thoughtful content.